Related Projects

- Project ID 3: Vertical Farm

- Project ID 4: Liquid Monitoring System

Control Systems

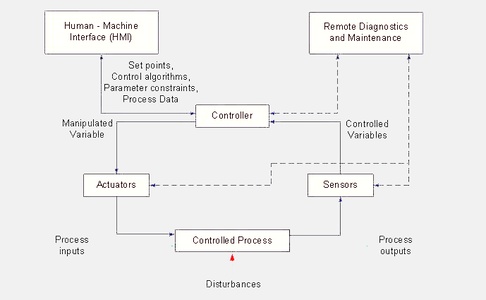

I design robust and intelligent automation systems that begin with a rigorous analysis of operational goals, failure

modes, and system dynamics. My approach is rooted in both engineering theory and practical implementation. I frequently

perform control system calculations—from designing closed-loop systems with specific damping ratios to calculating

precise current and voltage requirements for actuators and sensors—ensuring optimal performance and energy efficiency

from the ground up.

Sensor and actuator selection is guided not by cost alone but by accuracy tolerances, environmental durability, and

lifecycle value. I build intentional performance margins (typically 20–30% beyond required specifications) to guarantee

stability in edge-case scenarios and long-term reliability in demanding environments.

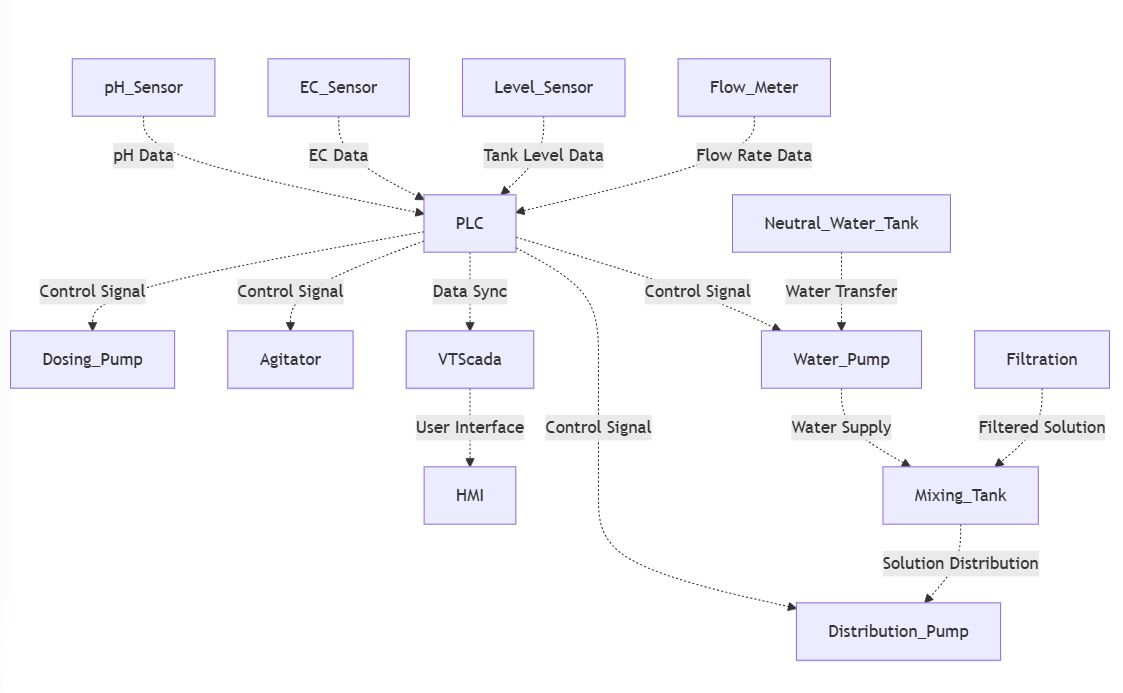

Depending on the application, I integrate lean microcontroller-based solutions for embedded control or industrial-grade

PLCs and RTUs for more complex, mission-critical operations. I also develop SCADA systems using platforms like VTScada

to enable intuitive real-time monitoring, remote control, and data logging across distributed processes.

My implementations prioritize maintainability and scalability through modular code design (IEC 61131-3, structured text,

C++, Python), clean documentation, and standards-driven commissioning workflows. I also handle real-time tuning of PID

and model predictive controllers, along with integration of industrial protocols like Modbus, OPC UA, and proprietary

vendor protocols.